Method for Making Aluminum Single Crystal Interconnections On Insulato…

페이지 정보

작성자 Malinda 댓글 0건 조회 3회 작성일 24-12-28 07:59본문

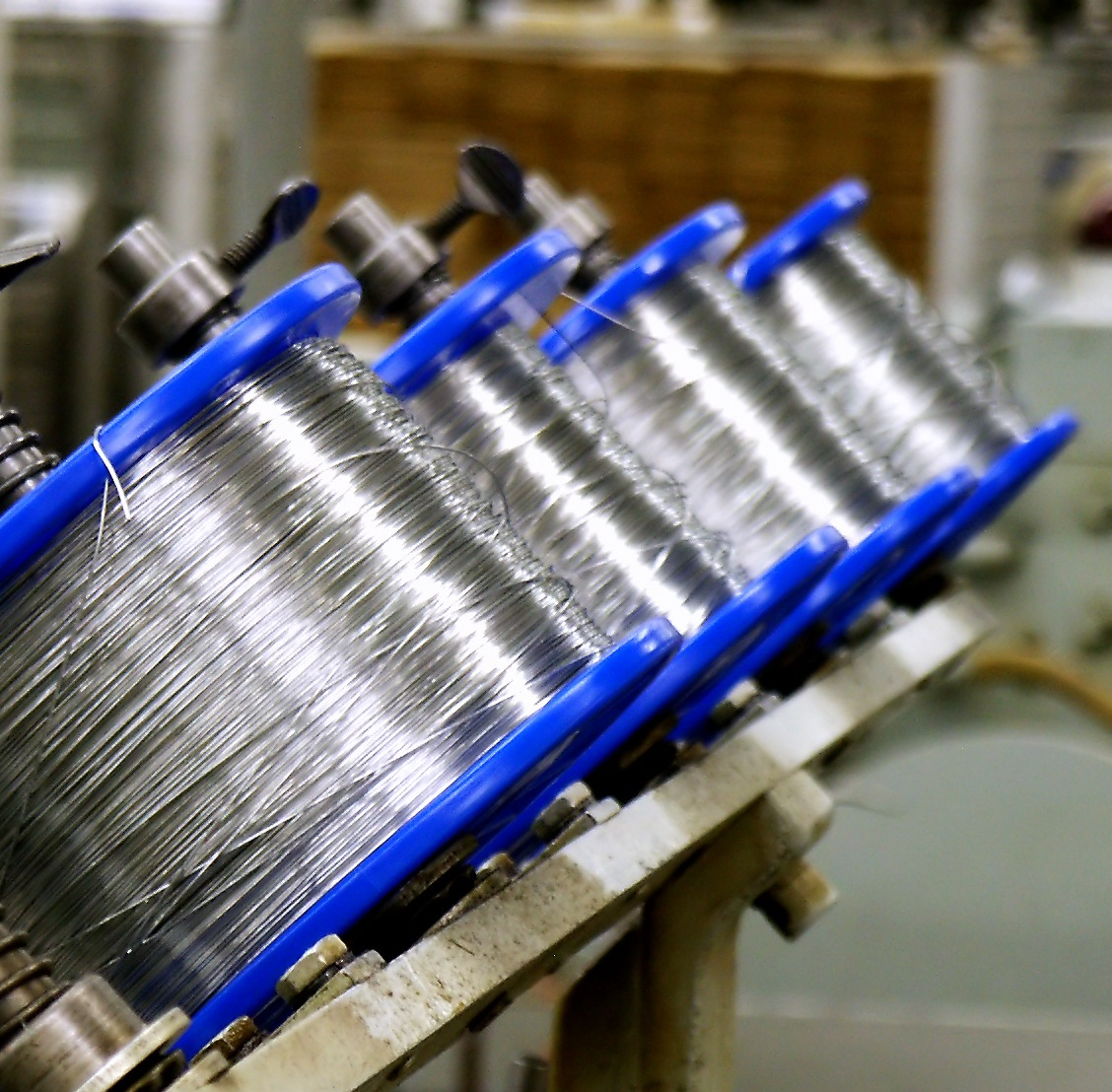

FIG. 7B shows that a bent portion of wiring 20 is bent in an angle of 60 and one hundred twenty levels. FIG. 7A shows that a bent portion of wiring 20 is bent in an angle of one hundred twenty levels. Identifying every crystal aspect from an angle thereof, the respective crystal sides were discovered as shown in FIG. 14. Moreover, by observing the cross sections of other crystal seeds, it was discovered that a cross sectional shape decided by the crystal facet was equal and the in-aircraft orientation of the crystal seed was controlled in the surface thereof in order to indicate the same orientation. In keeping with nonetheless one other aspect of the current invention, there's provided a way of producing a semiconductor machine comprising the steps of: forming a groove having a predetermined pattern shape on the floor of a substrate; forming a primary steel thin movie on the substrate; agglomerating the primary steel movie by annealing in order to fill the primary metallic into a minimum of a portion of the groove while formation of a local oxide movie thereon is suppressed; forming a second metal thin movie made of a same material as the primary steel thin movie, on the substrate with agglomerated first skinny film; and patterning the first and second skinny movies.

In the same determine, the vertical axis thereof signifies an X-ray intensity, so that the greater the intensity turns into the better the crystallization thereof is. Ar was the gasoline that was utilized within the sputtering, the background stress was less than 10.sup.-Eight Torr, the stress throughout the sputtering was 3.times.10.sup.-3 Torr, and the utilized energy was 6 KW, so as to type the Al film while suppressing the formation of the native oxide film on the Al surface. By this truth, it's clearly indicated that the additional preferred orientation is effected in a method where the first Al film is separated in order to type a crystal seed (though not proven) and the second Al movie is grown primarily based on the crystal seed. As for materials resembling Cu and Ag which have a decrease resistance than Al-containing material, Aluminum single wire it is difficult to type a compound having a high vapor strain. In view of the foregoing problems, an object of the present invention is to supply an electrode interconnection by which a most popular orientation regular to the substrate is additional improved, and an in-aircraft rotation of crystal grains in substrate face is suppressed in order to have a wonderful endurance towards stressmigration and electromigration.

In the same determine, the vertical axis thereof signifies an X-ray intensity, so that the greater the intensity turns into the better the crystallization thereof is. Ar was the gasoline that was utilized within the sputtering, the background stress was less than 10.sup.-Eight Torr, the stress throughout the sputtering was 3.times.10.sup.-3 Torr, and the utilized energy was 6 KW, so as to type the Al film while suppressing the formation of the native oxide film on the Al surface. By this truth, it's clearly indicated that the additional preferred orientation is effected in a method where the first Al film is separated in order to type a crystal seed (though not proven) and the second Al movie is grown primarily based on the crystal seed. As for materials resembling Cu and Ag which have a decrease resistance than Al-containing material, Aluminum single wire it is difficult to type a compound having a high vapor strain. In view of the foregoing problems, an object of the present invention is to supply an electrode interconnection by which a most popular orientation regular to the substrate is additional improved, and an in-aircraft rotation of crystal grains in substrate face is suppressed in order to have a wonderful endurance towards stressmigration and electromigration.

However, when used because the plug is the totally different metallic from the upper and/or lower interconnections, an interconnection steel atom transferred due to the electromigration and stressmigration phenomena is hindered from the switch thereof on account of the plug. In one facet of the present invention, there's offered a technique for making single-crystal aluminum interconnection, the method comprises the steps of forming a groove having a predetermined sample form on the surface of a substrate; forming a metallic film on the substrate while reaction with the surface of the substrate is suppressed; and agglomerating the metallic movie by in-situ annealing, wherein agglomeration of the metallic film is started before the metal movie reacts with the floor of the substrate as a result of annealing, whereas formation of a native oxide on the steel film is suppressed, and whereby the metal film is filled into the groove by annealing at a predetermined temperature for a predetermined time frame.

According to another aspect of the present invention, there's supplied a method of producing a semiconductor gadget comprising the steps of: forming a groove having a predetermined sample form on the floor of a substrate; forming a metal movie on the substrate; selectively removing the metal movie formed in an area other than the groove; eradicating a native oxide film formed on the metallic film; and agglomerating the metallic film by annealing in an vacuum atmosphere so as to fill within the steel movie into the groove while re-formation of the native oxide movie is suppressed. Moreover, in order to enhance the step protection at the time of Al film formation by sputtering, groove shapes similar to in FIG. 42A-42C could serve the purpose and be carried out to the first via tenth embodiments. In distinction thereto, the tactic wherein the Al is crammed into the groove of the interlayer insulator realizes that the stress is dispersed as described within the sixth and eighth embodiments Consequently, there's realized the electrode wiring structure by which the crystal grain boundaries do not happen in the bending portion or wiring connecting portion. Still another object thereof is to offer an electrode wiring structure by which there remains no mechanical stress, a contact resistance is reduced, and a heat radiating effect is improved.

According to another aspect of the present invention, there's supplied a method of producing a semiconductor gadget comprising the steps of: forming a groove having a predetermined sample form on the floor of a substrate; forming a metal movie on the substrate; selectively removing the metal movie formed in an area other than the groove; eradicating a native oxide film formed on the metallic film; and agglomerating the metallic film by annealing in an vacuum atmosphere so as to fill within the steel movie into the groove while re-formation of the native oxide movie is suppressed. Moreover, in order to enhance the step protection at the time of Al film formation by sputtering, groove shapes similar to in FIG. 42A-42C could serve the purpose and be carried out to the first via tenth embodiments. In distinction thereto, the tactic wherein the Al is crammed into the groove of the interlayer insulator realizes that the stress is dispersed as described within the sixth and eighth embodiments Consequently, there's realized the electrode wiring structure by which the crystal grain boundaries do not happen in the bending portion or wiring connecting portion. Still another object thereof is to offer an electrode wiring structure by which there remains no mechanical stress, a contact resistance is reduced, and a heat radiating effect is improved.

댓글목록

등록된 댓글이 없습니다.